Clinching Process Monitoring

Detailed Information for High Quality Clinching

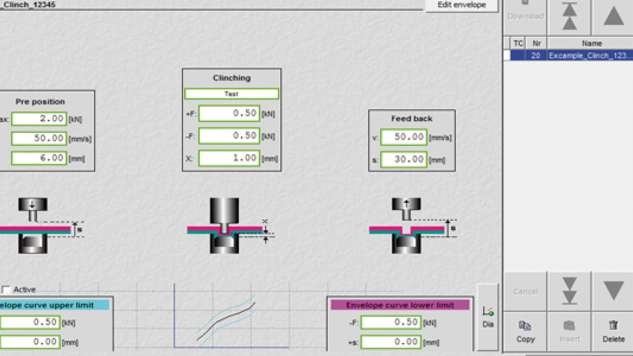

The process monitoring CEP 400T has been specifically designed for the TOX®-Joining process. The CEP 400T helps you to monitor and document all quality parameters related to the TOX®-Clinching process.

Force sensors measure the press force during the joining process. A position sensor monitors the cylinder travel to achieve the quality control dimension "X". Once the position sensor signals that the dimension "X" has been reached (bottom end position), then the measured force values are compared to the nominal values. The TOX®-Joint is OK when the measured force value falls within the preset force range. The resulting bottom thickness "X" is proportional to the shear and pull strengths of the joint, as long as the joining parameters and expected tool life are observed and maintained.

Functions of the CEP 400T

Optional features

*With field bus connection, individual evaluation IO/NIO and end values are displayed, independent of the number of measuring channels in the device.

Contacto MX: +52 1 844 242 1300 Formulario de contacto |

Cookie Information Nuestra empresa utiliza cookies para representar de forma óptima nuestra página web. En las configuraciones de su navegador podrá impedir o regular las cookies. |