With TOX®-EdgeUnit, every TOX®-ElectricPowerDrive becomes an intelligent component within the network

- Supply with 24 V

- Internal fieldbus: EtherCAT

- Status LED

- Integrated memory for

- maintenance counter, stroke counter

- drive date, calibration factor

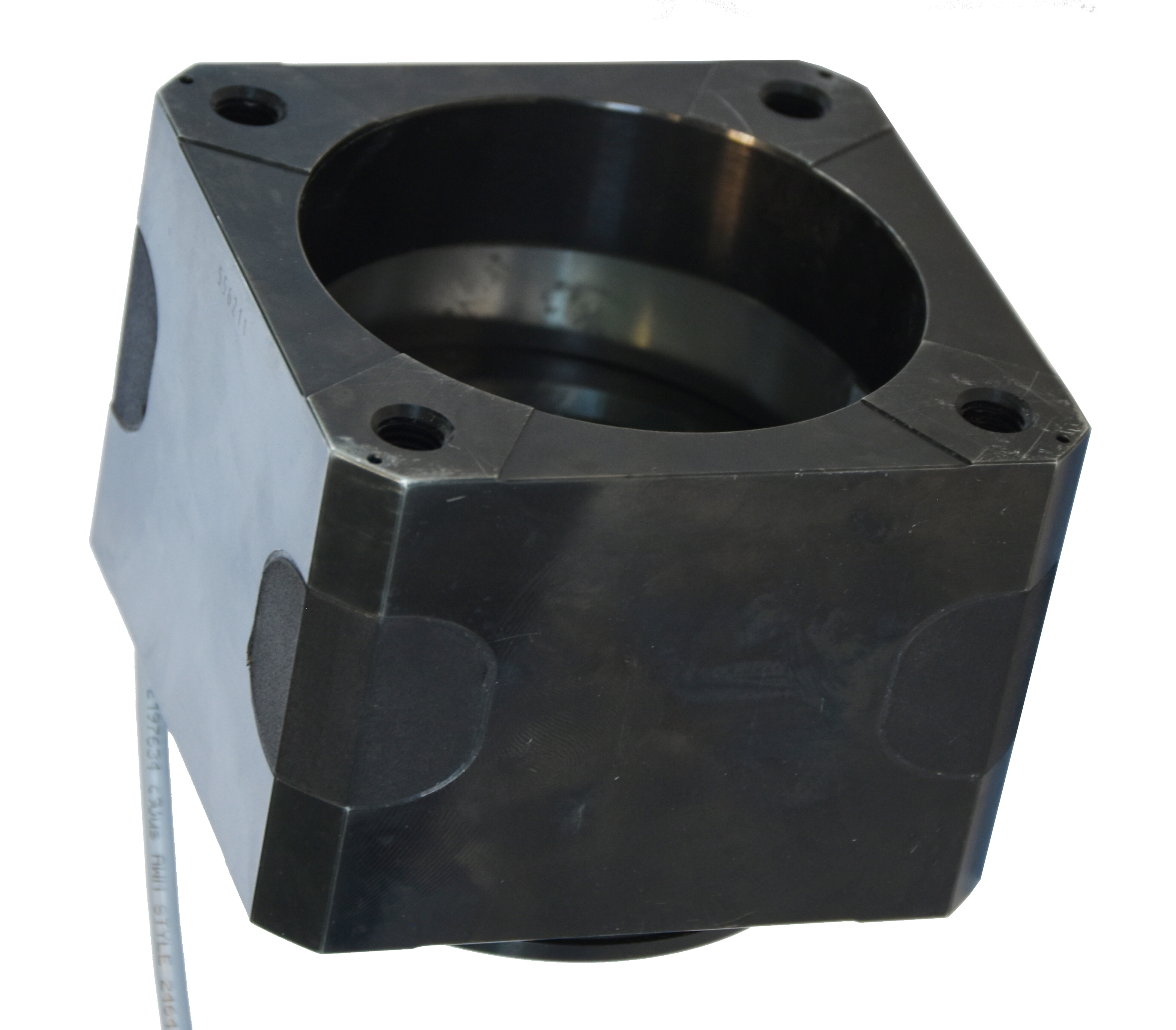

Mechanics & Sensors of the servo press drives

The intelligent servo press with precision mechanics

With TOX®-EdgeUnit, every TOX®-ElectricPowerDrive becomes an intelligent component within the network

Extend the servo press without additional hardware with the components selected by you by means of comprehensive interfaces on the TOX®-ElectricPowerDrive:

to the accessory sensor overview

A typical application example is pressing.

Typical application examples are punching, press applications with high joining speeds or press applications in limited installation spaces.

Let us know your requirements - we will dimension the optimum drive system for you. We can optimize your solution with our versions:

|

Contacto

MX: +52 1 844 242 1300

Formulario de contacto

|

|

Cookie Information

Nuestra empresa utiliza cookies para representar de forma óptima nuestra página web. En las configuraciones de su navegador podrá impedir o regular las cookies. |