TOX®-Powerpackage Special Models

Powerpackage individual - especially made for your application

For our TOX®-Powerpackages we offer special solutions. Those are more than accessories and have to be ordered as a complete type of drive. Also, the decision of the assembly version has to be made with the design approval.

Special versions of the TOX®-Powerpackage with additional integrated functions make a good product even better.

The new integrated damping option allows an adjustable constant speed of the cylinder working rod during the approach stroke and powerstroke, independent of the working forces. Now it is possible to almost fully compensate a stick-slip-effect at a press-in process, and when stamping compensate the sudden acceleration of the working rod when the opposing force is removed.

Press-in applications:

Depending on the application, chattering effects may occur during the press-in operation, the so-called stick-slip effect. This effect induces strongly fluctuating progressions of force/travel making a reliable process control difficult. And this chattering also generates undesirable press-in results and increased noises. With the new damping function ZED, this effect is almost completely compensated. The press-in operation happens controlled at a constant speed. The force-travel curves can be precisely monitored and evaluated.

Punching applications:

The breakthrough effect at the end of a punching operation causes an abrupt drop of the counterforce. This results in an instantaneous high acceleration of the cylinder working rod. The punching shock causes high noise levels and premature wear of the tools and the machine. With the new damping function, ZED applied, the speed of the working rod remains nearly constant. Thereby shocks are prevented at the end position and noise levels are noticeably reduced.

Advantages:

Options:

Advantages:

The maximum dampening stroke is approx. 7 mm.

| Accessory for: | S, K , X-S, X-K, X-AT |

A loss of air pressure will cause the unit to clamp on the cylinder rod. The energy of the drifting or falling load is used to generate the clamping force.

The rod catcher will prevent the cylinder rod from extending unless the static holding force is not exceeded.

The locking brake is kept open by air pressure.

The clamping force increases as the load increases. Internal springs force wedges to clamp the cylinder rod once the air pressure drops. The clamping force is released by applying air pressure and retracting the load.

The locking brake is single-acting.

Here you find a selection of special versions of the TOX®-Powerpackage perfectly designed for your exceptional application.

Please contact us for any special solutions not found here. There is a large probability that the current, extensive collection of already designed and built TOX®-Powerpackage special executions contain a unit that meets your application. We will gladly check with you all possible alternatives.

All TOX®-Powerpackages are available with food grade oil and grease lubrication on request. Both lubricants are certified according to USDA-H11 and are used wherever there is a chance of occasional, technically unavoidable contact with food.

All TOX®-Powerpackages can be supplied with rust protection on request. All individual parts are either plasma nitrided, galvanized or primed and painted, wherever stainless steel is not generally used. These devices are particularly suitable for use in the food and packaging industries.

This section lists additional, integrated features which can be selected when ordering a TOX®-Powerpackage. For several drive types, these options are already included as standard.

| Already equipped: | Q-S, Q-K, X-S, X-K, X-AT, S4-S170, K75-K170 |

| Accessory for: | K2-K50 |

The ZHD is a power bypass with hydraulic end position cushion in return stroke. It provides optimum cushioning of the working piston at the end of the return stroke. This feature is especially useful in applications with heavy tooling weight and high cycle speeds.

In the event of control errors, or the case of special applications, the strong acceleration of the working piston after punching through the material may cause a vacuum in the high-pressure oil chamber of the TOX®-Powerpackage which could lead to malfunctions.

Additionally it is also possible to use the bypass system for the realization of long powerstrokes.

The vacuum, an effect of the strong acceleration of the working piston, can be prevented with the patented TOX®-Powerpackage with integrated power bypass system ZLB.

Already equipped in TOX®-Powerpackages with ZHD

Accessory for: S1-S2, K1

Technical data

| Repeat accuracy: | ± 10 μm |

| Supply voltage: | 20 ... 28 V DC |

| Remaining ripple: | ≤ 0,5 Vss |

| Current consuption: | ≤ 150 mA |

| Electric strength GND | against housing 500 V |

| Output voltage: | 0 ... 10 V DC |

| Output voltage: | 10 ... 0 V DC |

| Load current: | ≤ 5 mA |

| Protection class: | IP67 |

The optional USB communication box for ZKW provides two outputs via USB interface.

Technical data

| Operating voltage: | UB 10 – 30 V DC |

| Residual ripple: | ≤ 15 % |

| Max. admissible current: | 1a 200 mA |

| Turn-on time: | ≤ 0,5 ms |

| Turn-off time: | 20 – 50 ms |

| Hysteresis: | 0.5 ... 1 mm |

Attention: When refitting the optional accessory ZHU, the total stroke of the TOX®-Powerpackage is reduced by 10 mm (S/K/AT 1-30) or 20 mm (HZ 5-48).

... and many more are described together with the Accessories for the TOX®-Powerpackage.

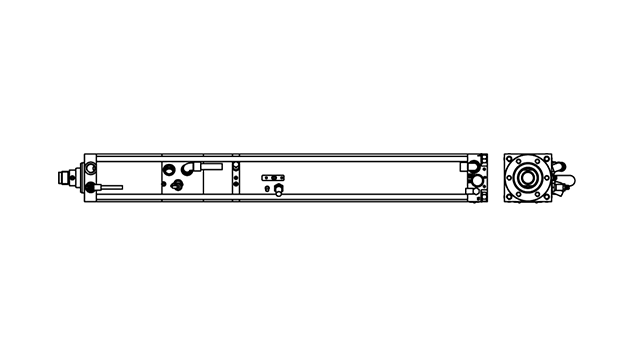

Mounting flange and connections on the TOX®-Powerpackage can be delivered in different orientations. The following section shows these available assembly versions for TOX®-Powerpackages.

Additionally several Z-design variants or customer-specific assembly versions are possible. Please contact us!

With a variety of clever accessories the powerpackage can be improved and taylored right for the application.

|

Contacto

MX: +52 1 844 242 1300

Formulario de contacto

|

|

Cookie Information

Nuestra empresa utiliza cookies para representar de forma óptima nuestra página web. En las configuraciones de su navegador podrá impedir o regular las cookies. |