TOX®-FlexPress Compact

The industrial requirements for data acquisition and evaluation of the assembly processes of several components are continuously growing. To ensure a consistently high quality, it is no longer sufficient to manually declare assembled components as in order or not in order. The traceability of individual processes is of particular relevance here.

Safe production, which corresponds with the highest quality requirements, is only ensured through the identification and analysis of your process data and valid database.

TOX® FlexPress Compact

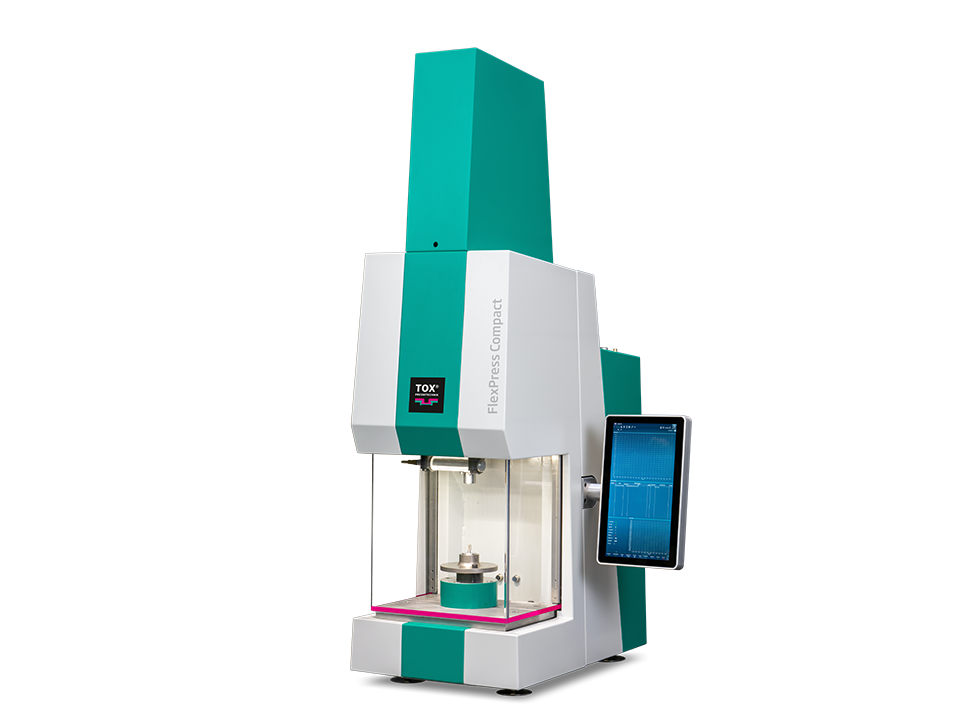

The TOX® FlexPress Compact provides an electric press workstation for precise work results with seamless process monitoring.

Proven mechanics and know-how spanning several decades in press manufacturing meet process monitoring with the latest features and a sophisticated control concept.

Available in four versions: 5kN, 10kN, 30kN, 60kN

Proven mechanics, compact footprint

The electric press with monitoring is driven by the electromechanical servo presses of the TOX® ElectricDrive series. Our EQe-K and EXe-K ElectricDrives with integrated force and travel sensors are used in this press series.

The press design consists of a welded frame with the drive, safety equipment, housing and drive cover. This design promises a long service life and a low noise level for operators.

The operation of the FlexPress Compact is not only very quiet, but it also has a small footprint. All technologies mastered by TOX® are realized on in just 425 mm x 703 mm x 1402 mm. Even with the base frame/table, this corresponds to less than 1 square meter in your workshop.

Intuitive control concept – maximum safety

You will not find a control cabinet on the FlexPress. The often-bulky control enclosure is inside the press with the new ElectricControl Core concept.

The operators control the assembly workstation via the 13" UDI Panel. It is an operating unit, process monitoring screen and analysis tool in one – a Universal Data Interface.

Ergonomic requirements of the workers were given special consideration for the FlexPress Compact

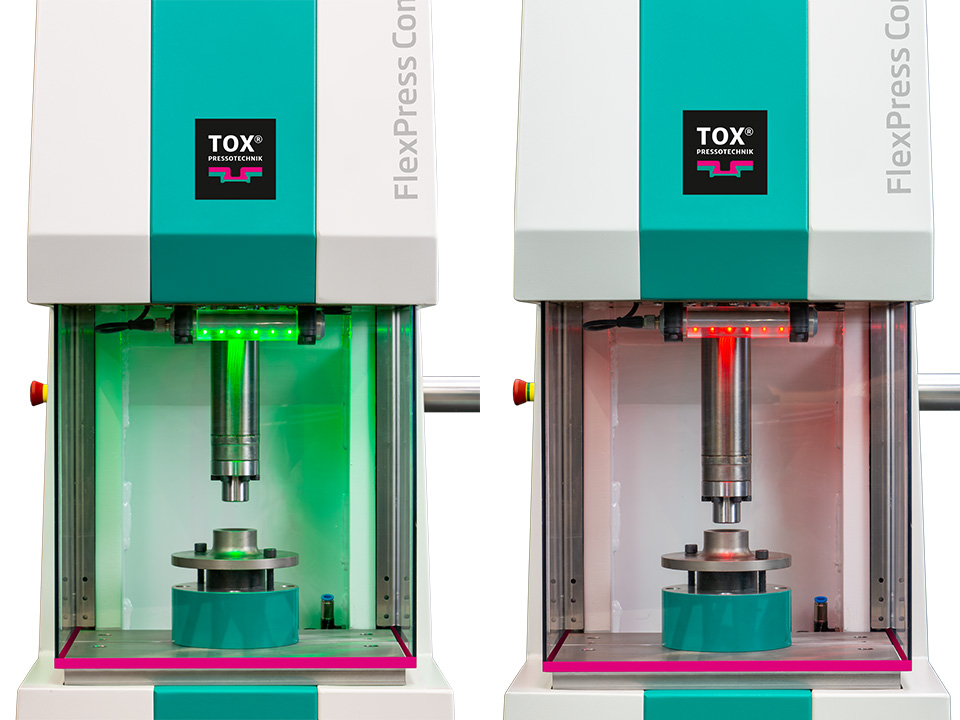

Another highlight of the control concept is the RGBW-illuminated work area. This illumination acts as status display following completion of a cycle. In case of a green light, the next work step can follow immediately. In case of a red light, the component does not meet the required quality windows. The advantage of the immediate optical feedback for the operators is that their focus remains on the work area, not switching to the monitoring screen.

Furthermore, additional ergonomic and safety-relevant aspects have been implemented:

- Electrical safety door - safe, quiet and quick

- Contoured housing for optimum visibility of the tools and components, independent of the working height

Your process data: From recording to evaluation

Whether you are working with the TOX®-Software as the operator, maintenance staff, process engineer, commissioning engineer or quality manager, the HMI impresses with customizable screens as well as clear, freely definable dashboards. Parameterization, operation, process monitoring, diagnosis and evaluation as well as quality management are integrated in the TOX® Software and TOX® SystemControl Core:

- Ethernet transfer of process data archiving and much more

- 5000 diagram points per process

- 10 process display in a diagram

- 5 windows per process freely definable

The FlexPress Compact is perfectly prepared for functional extensions in the tool room:

- 2 M12 inputs for component sensors

- 1 Ethercat connection for intelligent bus module

- 1 pneumatic connection

Flexibility of application

All technologies mastered by TOX® are realized in the assembly workstation. Whether it is accurate pressing in and pressing on processes, or simple clinch connections – the FlexPress Compact comprehensively covers the technology portfolio of TOX®.

The simple set-up of the desired process and a quick tool change ensure maximum flexibility for the application.

For example, the electric pres with monitoring enables the production of prototypes in small quantities early in the shift, then, with an easy change-over, series production of other components later.

You can also get the associated tools in accordance with your ideas and wishes directly from TOX® PRESSOTECHNIK at the same time.

Options

Press functionality can be expanded via an intelligent bus module in the work area.

The FlexPress Compact is already prepared for the following options:

- Spray unit

- Manual or automatic tensioners

- Additional component sensors

- Additional external force sensor

- Additional external travel sensor

- Pneumatic valves

- Electrical actuating drives

- Manual scanner via USB

- External start button